NeoPAC®

NeoPAC®은 50여건의 특허등록을 한 이미지센서 패키징 기술로,

센서업계 선두회사들인 일본 Sony, 미국 TI, 중국 Galaxy Core, 한국 SK hynix 등

다수 고객사에 이미지 센서 패키징 서비스를 제공하고 있습니다.

GLOBAL COMPANY iWIN PLUS

Encapsulation

NeoPAC® Encap 기술 이란?

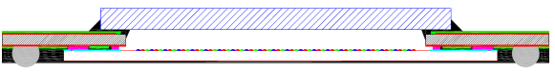

- NeoPAC® Encap은 NeoPAC® II Normal 구조에 Silica Filler가 함유된 Epoxy로 취약한 구조를 보강하여 신뢰성을 한단계 Upgrade시킨 NeoPAC® 제품기술을 말합니다.

- Silicon Sensor Chip의 측면 및 하면을 에워싸는 Epoxy Encapsulation 기술

- Sensor Chip과 기판 사이의 Flip Chip Solder Joints를 둘러싸는 Epoxy 보강기술(Underfill)

- 주변부 Solder Balls을 둘러싸는 Epoxy 보강기술

- NeoPAC® Encap 은 패키지 상면 Glass Filter를 둘러싸는 Epoxy 보강구조도 가능

NeoPAC® II Normal

NeoPAC® Encap 하면

NeoPAC® Encap 상하면

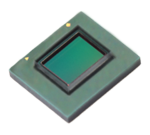

실물이미지 / NeoPAC® Encap

| Image Sensor for Automotive (AEC-Q100) | ||||

|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

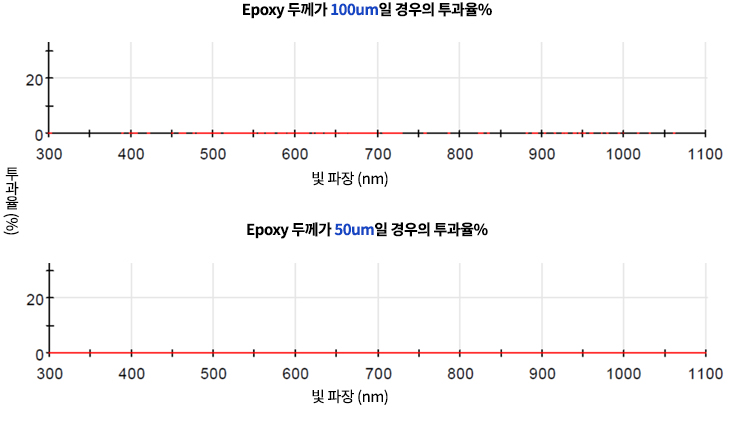

빛 차단 특성

- NeoPAC® Encap Epoxy는 빛 차단 특성이 매우 우수함

- 가시광선 영역 뿐만 아니라, IR 영역의 빛까지도 효과적으로 차단함

- 100um 두께의 경우, 전 파장 영역에서의 빛이 완벽하게 차단됨

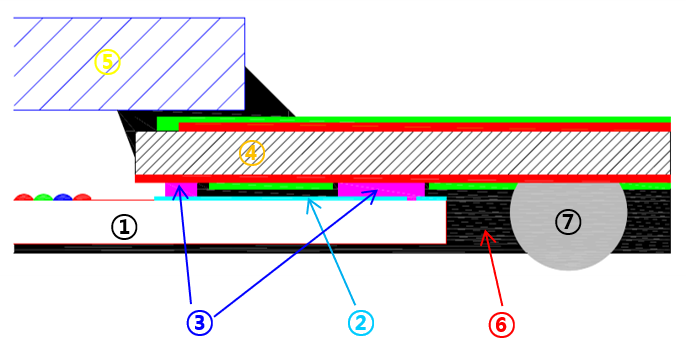

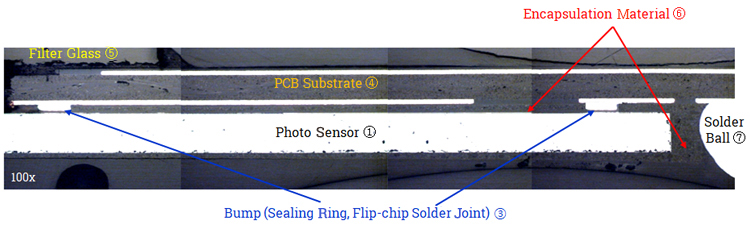

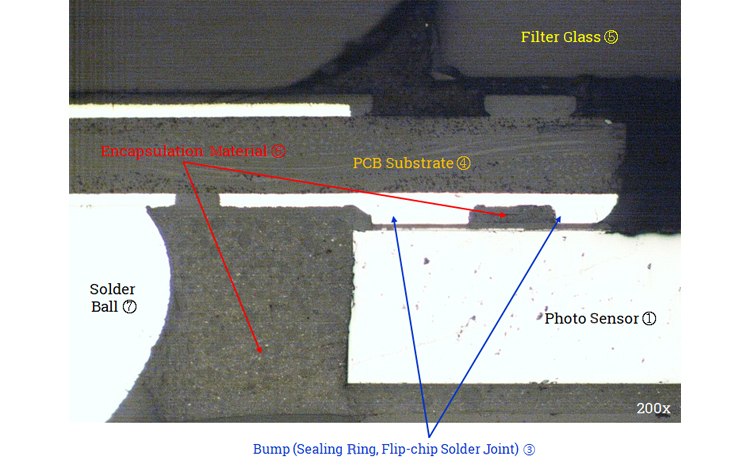

Cross-section View /

NeoPAC® Encap

Schematic View

| No | Description | No | Description |

|---|---|---|---|

| ① | Photo Sensor | ⑤ | Glass / Filter Glass |

| ② | SBL (Stress Buffer Layer) | ⑥ | Encapsulation Material |

| ③ | Bump (Sealing Ring , Flip-chip Solder Joint) | ⑦ | Solder Ball |

| ④ | PCB Substrate |

Cross-section View

Cross-section View / 확대이미지

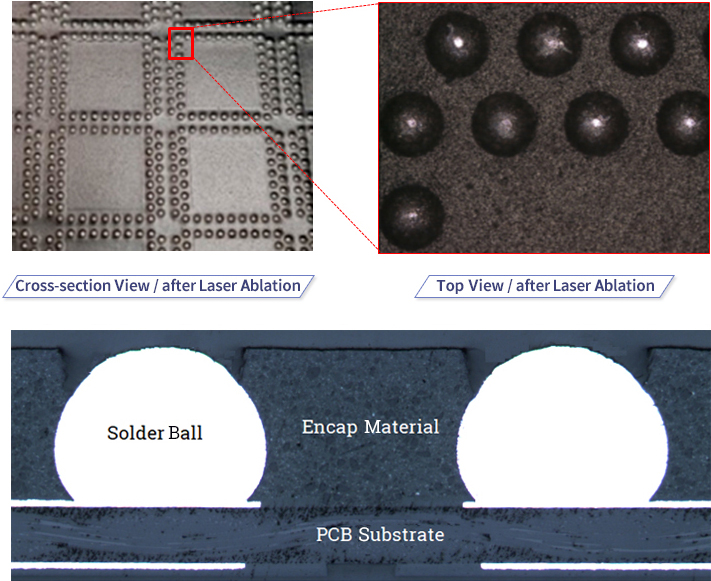

Solder Ball Opening

(Laser Ablation)

Solder Ball Laser Opening

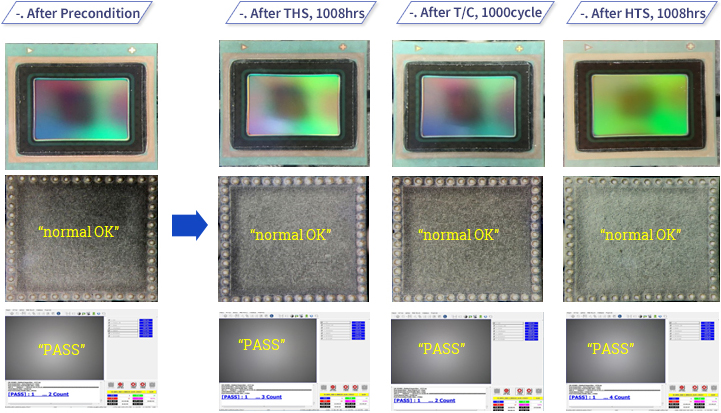

신뢰성 평가결과 NeoPAC® Encap

Reliability Test Result / PKG Level

| Device | Item | Condition | Sample Q’ty | Image Test Result | Summary | |

|---|---|---|---|---|---|---|

Function Test fail Q’ty |

Image Test failQ’ty |

|||||

NeoPAC® (S社 8Mega) |

Pre |

125°/24hrs, 30°C/60%-192hrs ,Reflow3x (JEDEC Level.3) |

135ea |

0ea |

0ea |

pass |

THS |

85°C/85%, 1008hrs |

45ea |

0ea |

0ea |

pass |

|

TC |

-55°C~125°C, 1000cycle |

45ea |

0ea |

0ea |

pass |

|

HTS |

150℃, 1008hrs |

45ea |

0ea |

0ea |

pass |

|

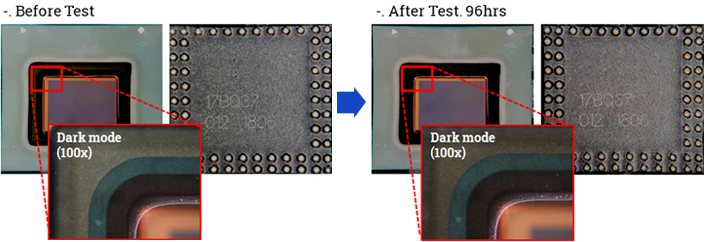

Reliability Test Result / Unbiased-HAST

[ Test Condition ]

[ Image Test Results ]

Cell. |

Sample |

after UHAST 48hrs |

after UHAST 96hrs |

Summary |

||

|---|---|---|---|---|---|---|

Image Test Fail /Q’ty(rate) |

V.I Fail /Q’ty(rate) |

Image Test Fail /Q’ty(rate) |

V.I Fail /Q’ty(rate) |

|||

Pre-con uHAST진행 |

20pkgs |

0/20 (0.0%) |

0/20 (0.0%) |

0/20 (0.0%) |

0/20 (0.0%) |

All “PASS” |

[ Representative Photos ]

Reliability Test Result / Phone Drop Test (Board Level)

[ 평가 시료군 ]

Cell.1 S社 8Mega제품 / NeoPAC® EncapCell.2 S社 8Mega제품 / NeoPAC® II Normal

[ 평가 조건 ]

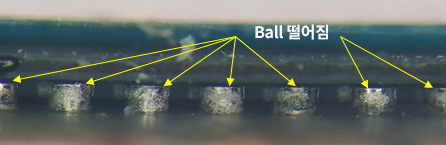

[ Drop Test Result & Failure Mode ]

시료군 |

Sample Q’ty |

Drop Test후 Fail Rate(%) |

Total Fail Rate(%) |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

1time |

2times |

3times |

4times |

5times |

6times |

7times |

9times |

10times |

|||

NeoPAC® Encap |

10pkgs |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

NeoPAC®II Normal |

10pkgs |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

0/10pkgs (0.0%) |

2/10pkgs (20.0%) |

4/10pkgs (33.3%) |

4/10pkgs (40.0%) |

효과적인 패키징 서비스를 제공하는 아이윈플러스입니다.